Hatch 100% into quality DOC

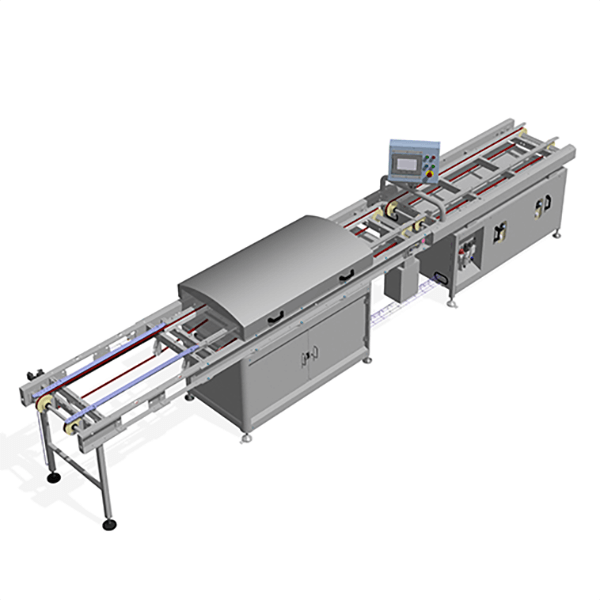

What it is

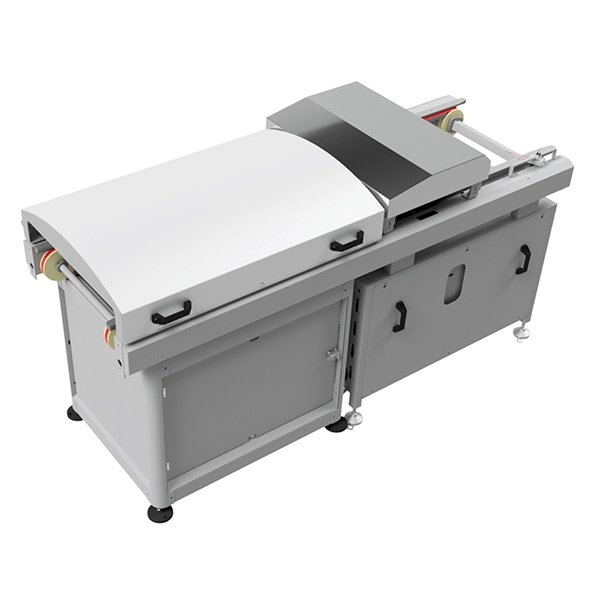

The innovative Ovosense®, identifies and marks the upside-down eggs. Ovosense® improves the hatchery output by offering fast, simple and effective egg setting analysis.

How it works

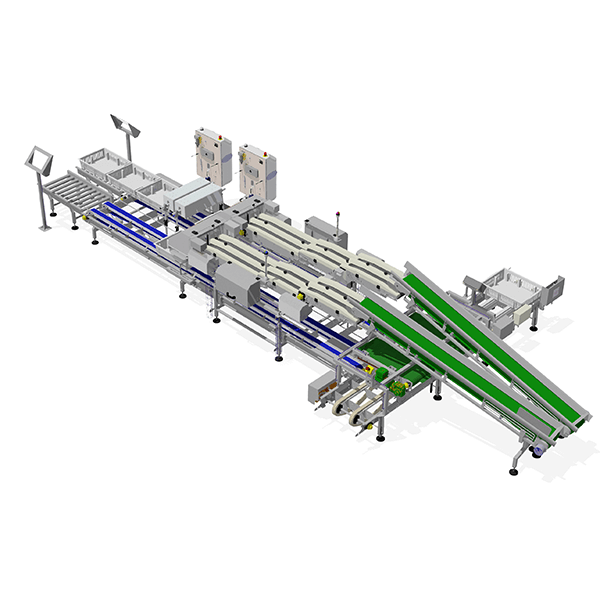

- Eggs coming from the breeder farms are normally transferred into hatchery trays.

- During this step, eggs can be wrongly positioned. These are called upside-down eggs.

- Via innovative sensors, Ovosense® detects eggs that are located upside down and marks them.

- Then the marked eggs can be manually set properly.

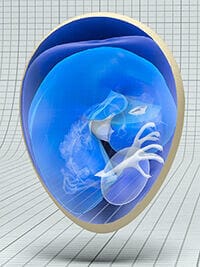

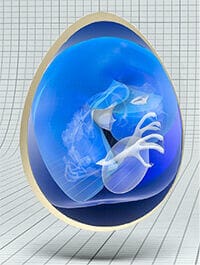

What is an upside-down egg?

PROPER SETTING

Embryo's head is towards air chamber in the blunt end. The embryo will use the air chamber to breath at hatch.

UPSIDE-DOWN EGG

Embryo's head is located away from the air chamber. The embryo cannot reach the air chamber to breath at hatch.

Equipment features

- Non Operator Dependant: all the eggs are well set

- High Speed Solution: reach up to 90,000 eggs analysed/hour

- Massive ROI, specially with young flocks and round-eggs breeds

- High accuracy: detection accuracy is reaching 99.9%

Why is it so important?

Embryos from upside-down eggs will not hatch regularly. If they do, they are normally discarded as cull chicks.

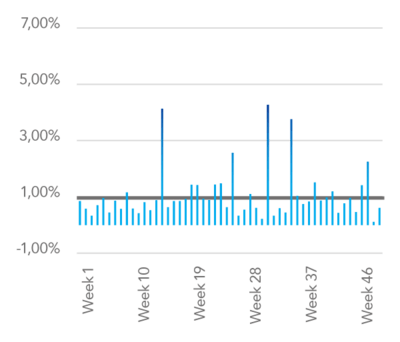

On average, 1% to 3% of eggs delivered to the hatchery would be upside down depending on the automation level. Identification of upside-down eggs before incubation gives a chance for 100% of the fertile eggs to produce a good day-old chick.

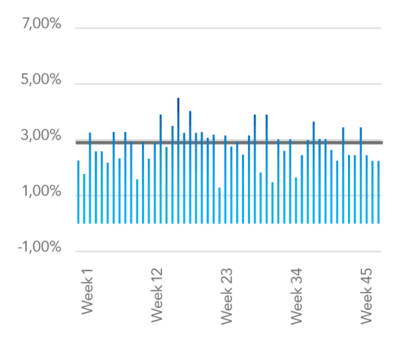

Case A: Yearly data from a non-integrated hatchery, shows an average of 1.04% upside-down eggs.

Case B: Yearly data from an integrated hatchery, shown an average of 2.82% upside own eggs.

- 1% upside down eggs represents around 489,000 day-old-chicks.

Need more information?

Maximize Hatchery Efficiency with Ovosense®

Why Ovosense® is Essential for Your Hatchery

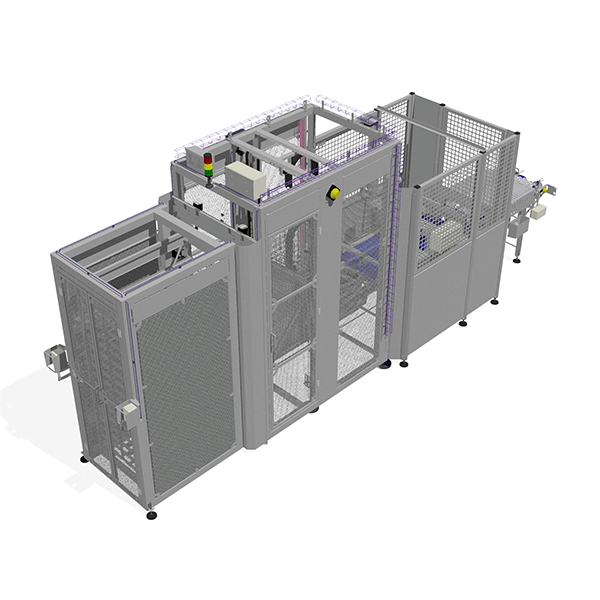

Ovosense® by Ceva Ecat-iD is a game-changer in hatchery management, designed to ensure that every egg has the best chance of hatching into a healthy chick. By identifying and marking upside-down eggs, Ovosense® significantly improves hatchery output through fast, simple, and effective egg setting analysis.

Key Features of Ovosense®

- Non-Operator Dependent: Ensures all eggs are correctly set without the need for constant supervision.

- High-Speed Solution: Capable of analyzing up to 90,000 eggs per hour, making it ideal for high-volume hatcheries.

- Massive ROI: Particularly beneficial for young flocks and round-egg breeds, offering substantial returns on investment.

- High Accuracy: Achieves a detection accuracy of 99.9%, ensuring minimal errors and maximum efficiency.

Importance of Proper Egg Setting

Proper egg setting is crucial for the successful hatching of chicks. Upside-down eggs, where the embryo's head is away from the air chamber, often fail to hatch or result in cull chicks. Identifying and correcting these eggs before incubation can significantly increase the number of healthy day-old chicks.

Impact on Hatchery Performance

- Increased Hatch Rates: By ensuring that all eggs are properly set, Ovosense® helps maximize hatch rates.

- Reduced Waste: Minimizes the number of cull chicks, leading to more efficient use of resources.

- Improved Productivity: Enhances overall hatchery productivity by reducing the time and effort needed for manual egg setting.