Egg Separator

What it is

- Ecat-iD's eggs and chicks separator solutions have the ability to allow saving time and labour costs.

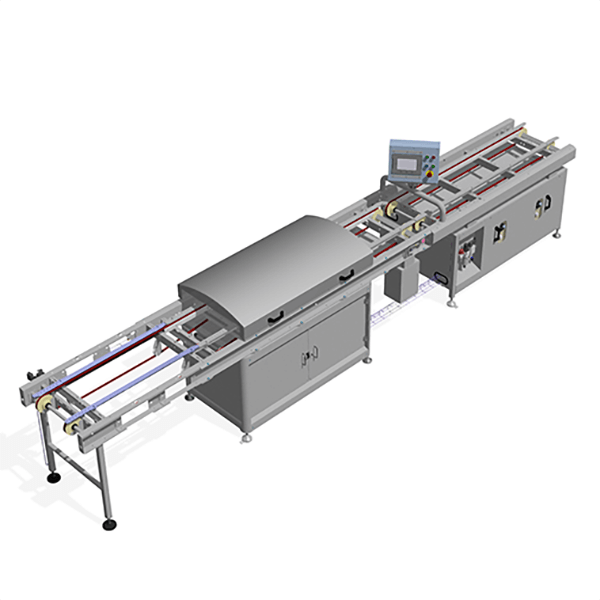

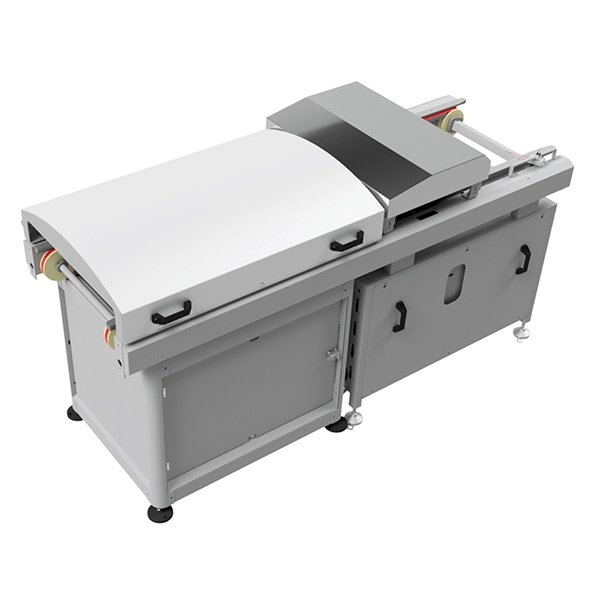

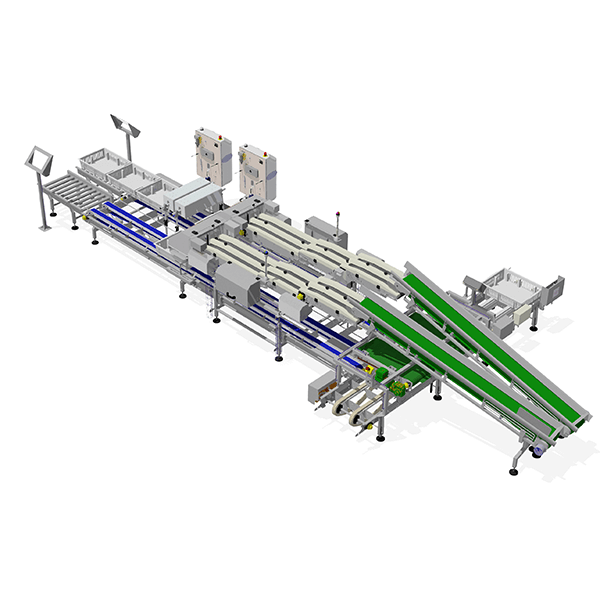

- This machine was carefully and efficiently made to allow chicks to pass through rollers onto a conveyor below, having egg-shell waste automatically separated and carefully removed. Special care is taken to minimize stress to chicks with adjustable belt speed and drop heights, achieving a throughput speed that can reach 90,000 chicks per hour.

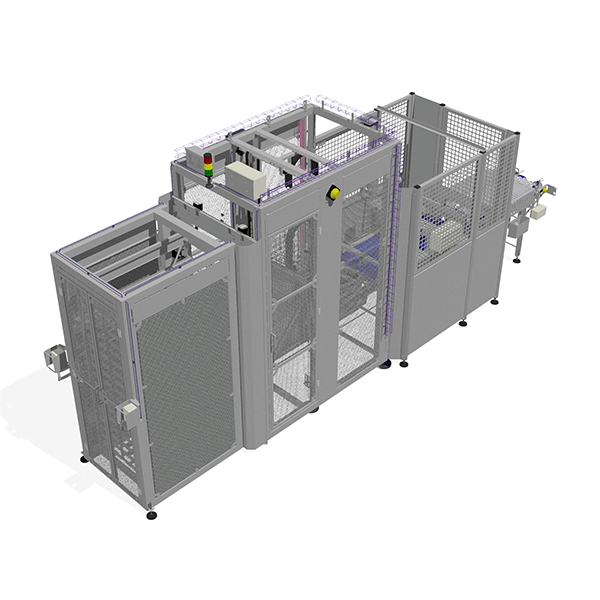

- Different configurations available, depending on the room dimensions in the hatchery. This machine is compliant with different tippers. Safety of egg and chick separator units are proven. Different options such as pre-washing, waste connection, are also available.

Ceva Ecat-iD's Egg Separator is an innovative solution that offers increased efficiency and cost-saving advantages to hatcheries. The machine is designed to quickly separate eggs and chicks while minimizing stress to the young animals.

With its sophisticated features and cutting-edge technology, the machine helps hatcheries increase productivity while cutting labor costs. The system works by having chicks pass through rollers onto a conveyor below where eggshell waste is automatically separated and removed.

This revolutionary design reduces stress to chicks by adjusting belt speed and drop heights, leading to a high throughput speed of up to 90,000 chicks per hour. This makes it suitable for hatcheries of all sizes - from family-run operations to large industrial facilities.

Ceva Ecat-iD provides various configurations of its egg separator machine to fit room dimensions and maximize efficiency. Each model is compatible with various tippers, making integration into existing hatchery setups a breeze.

Ceva Ecat-iD places safety as a top priority, and our equipment has been rigorously tested and proven safe for use in hatcheries. With adjustable belt speeds and drop heights, chicks are handled gently while minimizing stress for their wellbeing.

Ceva Ecat-iD provides essential features, such as pre-washing and waste connection, to further streamline their operations. These upgrades aim to boost machine efficiency while offering even greater cost savings to hatcheries.