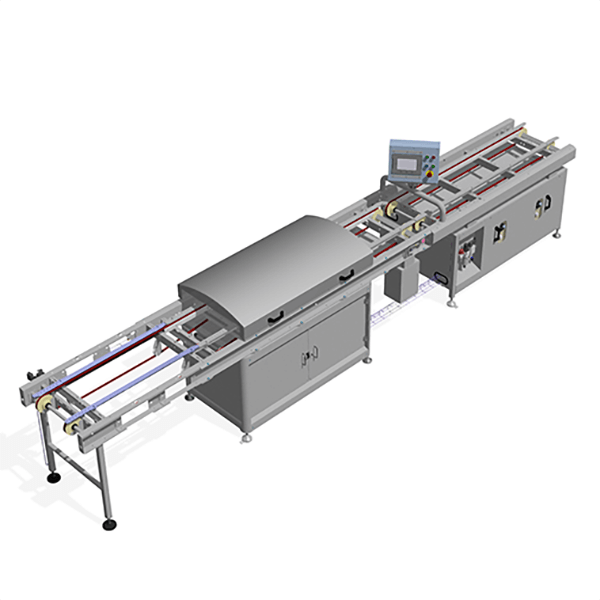

Tray Reloader

What it is

- Ceva Ecat-iD is offering fully automated tray reloading solutions, which can have both single or dual columns, and which are capable of processing up to 600 trays per hour depending on setup.

- With its smooth transition from belt to trolley, there is a minimal risk of disturbance to the hatching trays, ensuring a safe journey from the egg processing line to incubator.

Enhance Efficiency with Ceva Ecat-iD's Tray Reloader

Maximize Productivity with Automated Tray Reloading

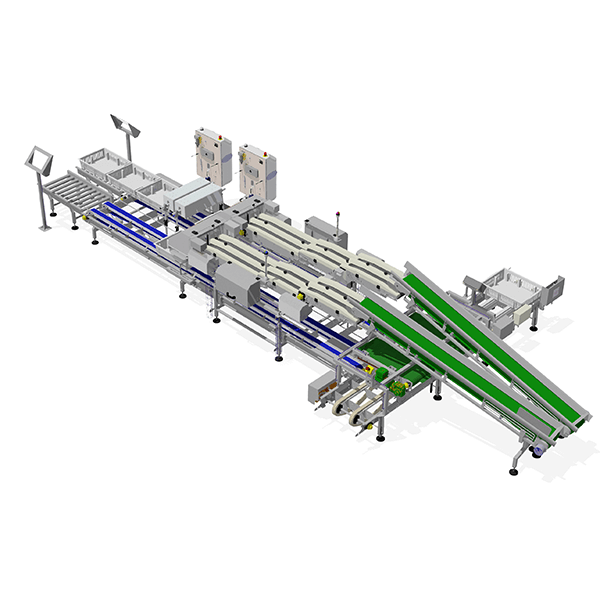

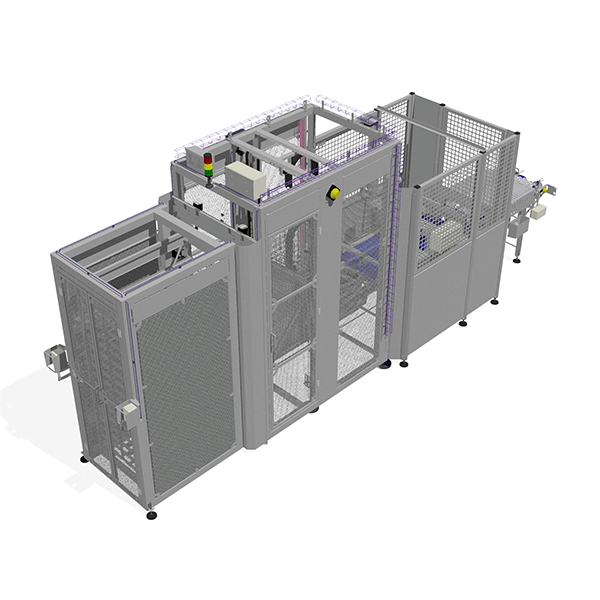

Ceva Ecat-iD introduces its fully automated tray reloading solutions, designed to streamline your hatchery operations. Our tray reloaders are available in both single and dual column configurations, capable of processing up to 600 trays per hour, depending on the setup. This high processing capacity ensures that your hatchery can maintain optimal productivity levels.

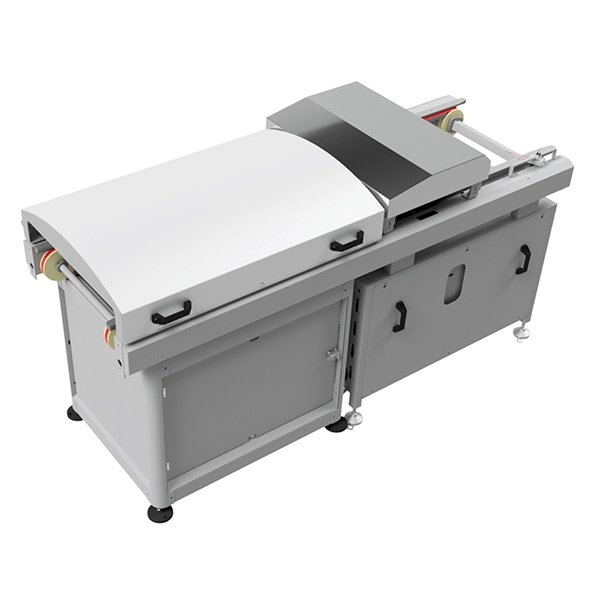

Smooth and Safe Transitions

Our tray reloaders are engineered to provide a smooth transition from belt to trolley, minimizing the risk of disturbance to the hatching trays. This careful handling ensures that the trays are safely transported from the egg processing line to the incubator, maintaining the integrity of the eggs and promoting successful hatching.

Why Choose Ceva Ecat-iD's Tray Reloader?

- High Processing Capacity: Capable of handling up to 600 trays per hour, our tray reloaders are designed to meet the demands of high-volume hatcheries.

- Customizable Configurations: Available in single or dual column setups, our solutions can be tailored to fit the specific needs of your hatchery.

- Gentle Handling: The smooth transition mechanism ensures minimal disturbance to the trays, safeguarding the eggs during the reloading process.

- Reliable Performance: Built with advanced technology, our tray reloaders offer consistent and reliable performance, enhancing the efficiency of your hatchery operations.